Placa refrigerada por líquido para disipación de calor de alta eficiencia

Datos del producto:

| Lugar de origen: | Dongguan, Guangdong, China |

| Nombre de la marca: | Uchi |

| Certificación: | SMC |

| Número de modelo: | placa enfriada por líquido |

Pago y Envío Términos:

| Cantidad de orden mínima: | 100pcs |

|---|---|

| Precio: | Negociable |

| Condiciones de pago: | T/T, PayPal, Western Union, Moneygram |

| Capacidad de la fuente: | 50000000pcs por mes |

|

Información detallada |

|||

| Característica: | Nuevas tecnologías y refrigeración de alta potencia | Proceso: | Enlaces epoxi |

|---|---|---|---|

| Material: | Aleación de aluminio, cobre | Forma: | Cuadrado |

| Certificado: | Las normas ISO 9001 incluyen:2008,ISO 14001:2004, ROHS | Proceso adicional: | Mecanizado CNC |

| Finalizar: | Limpio + anodizado | Tamaño: | tamaño personalizado |

| Solicitud: | Módulos de IGBG, dispositivos electrónicos, lasers | ||

| Resaltar: | Placa de refrigeración líquida para disipación de calor,Placa de refrigeración líquida de alta eficiencia,Placa refrigerada por líquido con garantía |

||

Descripción de producto

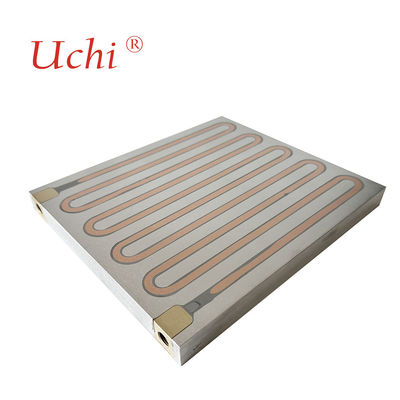

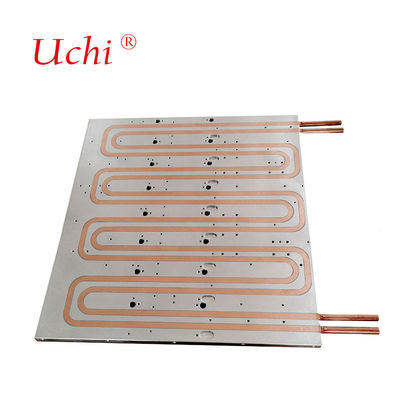

La placa de enfriamiento con agua líquida, también conocida como placa de disipación de calor de enfriamiento con líquido, es el componente central de intercambio de calor del sistema de enfriamiento con líquido.Su interior presenta canales de flujo especialmente diseñados donde circula el refrigerante para absorber y transferir calor de los componentes, liberándolo a través de radiadores o intercambiadores de calor.

- Personalización estructural:Diseño del canal de flujo (serpentino, paralelo, microcanal) adaptado a la potencia, forma y distribución térmica de los componentes

- Opciones de material:Leguras de aluminio (ligero), cobre (alta conductividad), acero inoxidable (resistente a la corrosión) o titanio para aplicaciones especializadas

- Rendimiento de sellado:Prueba de estanqueidad del aire a alta presión para evitar fugas de refrigerante y proteger la electrónica

- Interfaces estandarizadasConectores rápidos e interfaces roscadas para facilitar la integración del sistema

| El material | Tubos de aluminio, de aluminio y de cobre |

|---|---|

| Tamaño detallado | Diseñado a medida según las especificaciones del cliente |

| Ejemplo de servicio | Muestras de prototipos disponibles en una semana |

| Proceso de producción | Corte de placas de aluminio → Fabricación de ranuras → Encastramiento de tubos (saldado por fricción) → relleno de adhesivo epoxi → Mecanizado CNC → Limpieza → Inspección → Envasado |

| Tratamiento de la superficie | Desengrasado, anodizado (en negro), revestimiento de arena, pintura, cromado, marcado con láser |

| Norma de referencia | Las normas ISO 9001 incluyen:2008, ISO 14001:2004, ROHS |

| Experiencia de trabajo | Más de 10 años de fabricación profesional |

| Aplicación | Iluminación LED, inversores, máquinas de soldadura, dispositivos de comunicación, equipos de suministro de energía, industria electrónica, enfriadores/generadores termoeléctricos, sistemas de refrigeración IGBT/UPS,y otros dispositivos de alta potencia |

Nuestros disipadores de calor se someten a procesos de fabricación integrales que incluyen diseño, mecanizado CNC, soldadura por fricción, soldadura, ensamblaje, deslizamiento, extrusión, pruebas y tratamiento de superficie.

Nuestras soluciones de enfriamiento se utilizan ampliamente en transporte, computación de CPU, servidores, iluminación LED, equipos láser, aire acondicionado y cualquier producto eléctrico que requiera gestión térmica.

Todos los productos están empaquetados de forma segura en espuma de EPE y en cartones con reforzamiento de marco de madera.