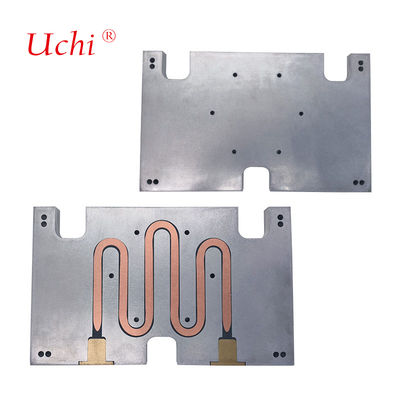

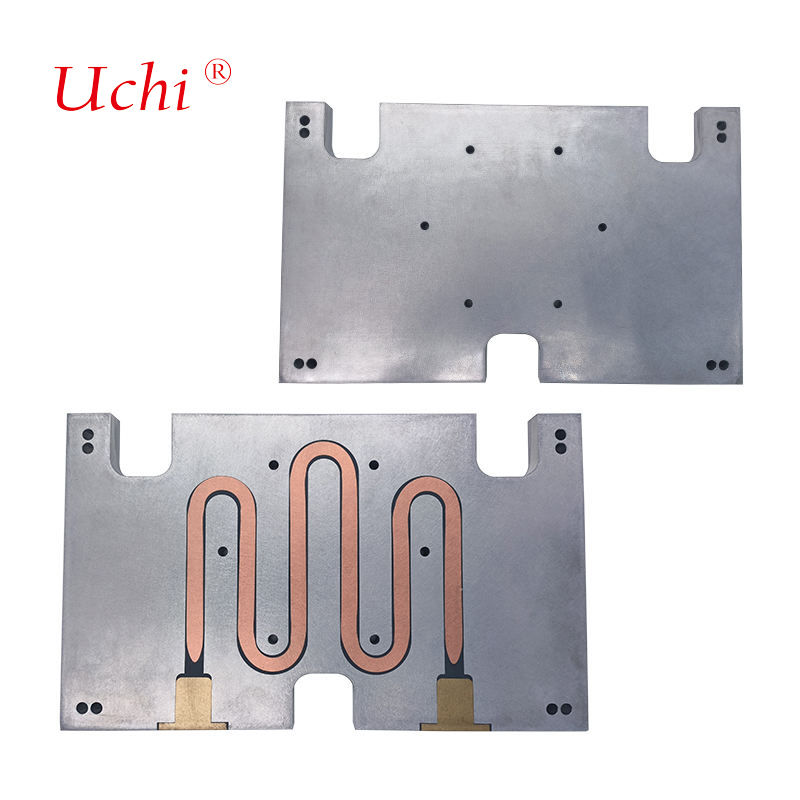

Placa de refrigeración líquida IGBT personalizada, placa de refrigeración de aluminio, placa fría de agua, placa de refrigeración líquida

Datos del producto:

| Lugar de origen: | Dongguan, Guangdong, China |

| Nombre de la marca: | Uchi |

| Certificación: | SMC |

| Número de modelo: | Placa de refrigeración líquida 12 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 100pcs |

|---|---|

| Precio: | Negociable |

| Condiciones de pago: | T/T, Paypal, Western Union, MoneyGram |

| Capacidad de la fuente: | 50000000pcs por mes |

|

Información detallada |

|||

| Material: | aleación de aluminio | Presión de trabajo: | 1,2 a 5 barras |

|---|---|---|---|

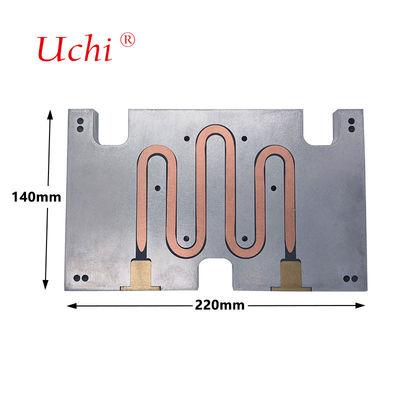

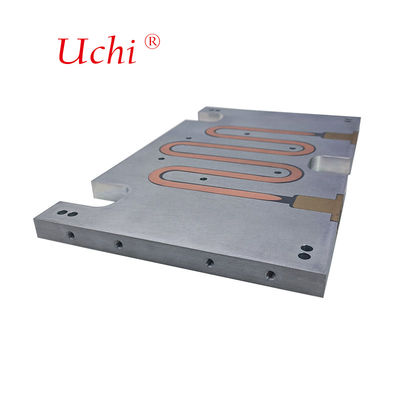

| Acabado superficial: | Acabado de fábrica o anodizado. | Tamaño: | 220*140*35 mm o tamaño personalizado |

| Tamaño de paquete único: | 23X15X4cm | Peso bruto único: | 2.400 kilos |

| Garantía: | 1 año | Aspereza de la superficie: | 1,2 micras |

| Planitud superficial: | Por debajo de 0,005 cm/cm | ||

| Resaltar: | placa de refrigeración líquida IGBT personalizada,Placa fría de agua de aluminio,Placa de refrigeración líquida con garantía |

||

Descripción de producto

Placa de refrigeración líquida IGBT personalizada Placa de refrigeración de aluminio

Nuestra placa fría de aluminio se procesa a partir de una aleación de aluminio de alta calidad, que ofrece una disipación de calor óptima para los módulos IGBT. Con una conductividad térmica de aproximadamente 202 W/(m*K), estas placas ofrecen un rendimiento excelente al tiempo que reducen el peso y el costo del sistema en comparación con las alternativas de cobre.

Ventajas del material

La aleación de aluminio ofrece ventajas significativas para las aplicaciones de refrigeración líquida:

- Rentable a 1/3 a 1/4 del precio del cobre

- Ligero con una densidad de 2,7 g/cm³ (frente a 8,9 g/cm³ para el cobre)

- Se puede fabricar en estructuras complejas de canales de flujo

- Resiste la corrosión del refrigerante manteniendo una conductividad térmica estable

Especificaciones del producto

| Materiales | Cobre (1020/1100), Aluminio (1060/1070/6063/6061) |

|---|---|

| Tratamiento de superficie | Chapado, Recubrimiento, Pintura, Anodizado, Chorro de arena, Roscado, Desbarbado, Cromado, Marcado láser, Desengrase, Pasivación, Limpieza |

| Procesamiento | Mecanizado CNC, Extrusión, Corte, Forja en frío, Fundición a presión, Estampado, Skiving, Plegado, Inserción, FSW (Soldadura por fricción-agitación), Soldadura, Epoxi, Niquelado, Doblado, Soldadura, Corte transversal, Fresado, Taladrado |

| Dimensión | Tamaño personalizado o dibujo del cliente requerido |

| Aplicación | Iluminación LED, Inversor solar, Equipos de suministro de energía, Ventilador médico, IGBT, Automoción eléctrica, Refrigeración líquida de escritorio, Dispositivo de comunicación, Enfriador de CPU, Equipos industriales |

| Dibujo aceptado | AutoCAD (dxf, dwg), PDF, 3D (STEP/IGS) |

Tecnología avanzada de soldadura fuerte

Nuestro proceso de soldadura fuerte al vacío une placas de aluminio utilizando un metal de aportación con un punto de fusión más bajo que el material base, creando uniones extremadamente fuertes sin flujo corrosivo residual. Esta tecnología de alta gama ofrece un calentamiento uniforme, un control preciso de la temperatura y elimina los requisitos de limpieza posterior, al tiempo que minimiza la distorsión de las piezas.

Aplicaciones clave

- Láseres y equipos médicos

- Enfriamiento de baterías de energía para vehículos eléctricos

- Electrónica de potencia y dispositivos de accionamiento de motores

- Sistemas de transmisión 5G por microondas

- Sistemas de energía renovable

- IGBT y sistemas semiconductores de potencia

- Centros de datos y aplicaciones de energía industrial

- Sistemas de defensa y aviónica

- Pilas de combustible y sistemas de tracción

Capacidades de producción

Nuestra planta de fabricación incluye 25 máquinas CNC, 10 máquinas de estampado, 2 máquinas de soldadura por fricción, 2 sopladores térmicos grandes, 4 máquinas de corte de alambre, 2 máquinas de chispa, 4 fresadoras y 3 rectificadoras.

Control de calidad

Mantenemos rigurosos estándares de calidad con 1 máquina de medición de coordenadas, 1 instrumento proyector, 2 máquinas de prueba de alta presión de agua, 4 máquinas de prueba de resistencia térmica y 2 máquinas de prueba de fugas de líquido.

Servicio al cliente

- Respuesta rápida a todas las consultas

- Precios competitivos con calidad garantizada

- Programación de producción eficiente

- Soluciones de transporte óptimas

- Soporte técnico integral

Preguntas frecuentes

¿Es usted una empresa comercial o un fabricante?

Somos un fabricante profesional de disipadores de calor y placas de refrigeración por agua con amplia experiencia y un sólido equipo técnico, con producción automatizada y mecanizada.

¿Ha exportado bienes antes y a qué regiones?

El 60% de nuestra producción total se exporta a Japón, India, Reino Unido, Canadá, EE. UU. y Brasil.

¿Cuántos empleados tiene?

Aproximadamente 100 empleados en los departamentos de ventas, compras, ingeniería, control de calidad, almacén y producción.

¿Puede proporcionar muestras si estamos de acuerdo con el diseño?

Sí, proporcionamos muestras para su confirmación antes de la producción en masa, junto con los dibujos técnicos si es necesario.

¿Qué métodos de embalaje utiliza?

Embalaje personalizado con cajas de cartón normales y tela a prueba de fugas o cajas de madera para una protección óptima durante el transporte.

¿Proporciona soporte técnico para problemas de productos?

Todos los productos se inspeccionan completamente antes del envío. Para cualquier problema, proporcionamos soluciones técnicas inmediatas.

Quiere saber más detalles sobre este producto