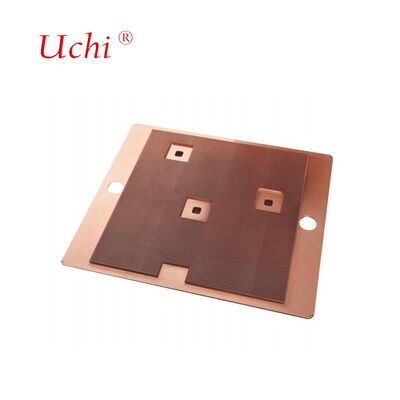

Sinque térmico de la serie 220 de 600 W de tubo de cobre con aleta de esquistos

Datos del producto:

| Lugar de origen: | Dongguan, Guangdong, China |

| Nombre de la marca: | Uchi |

| Certificación: | SMC |

| Número de modelo: | disipador de calor de aleta raspada 04 |

Pago y Envío Términos:

| Cantidad de orden mínima: | 100 piezas |

|---|---|

| Precio: | Negociable |

| Condiciones de pago: | T/T, Paypal, Western Union, MoneyGram |

| Capacidad de la fuente: | 50000000pcs por mes |

|

Información detallada |

|||

| Servicio de procesamiento: | Cortar, Punzonar, Desenrollar, Doblar, Taladrar | Temperamento: | T3 ~ T8 |

|---|---|---|---|

| Embalaje: | Bolsa de PE Cartón | Tolerancia: | ±1% |

| Estándar: | Disipador de calor de aluminio de calidad media y alta. | Ancho: | De acuerdo con la demanda del cliente |

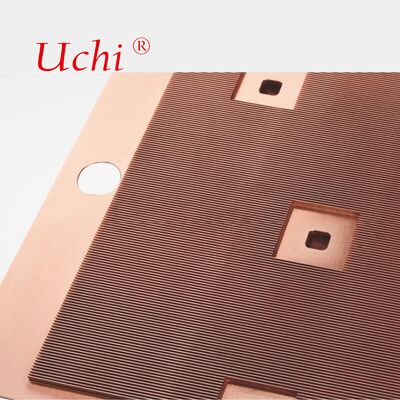

| Material: | Acero inoxidable, aluminio, bronce | Tecnología: | CNC y biselado |

| Espesor: | 0.5-2.5 mm | Solicitud: | Industrial, puerta, marco, disipador de calor LED |

| Calificación: | Serie 6000 | Vida de la fan: | 100000 horas |

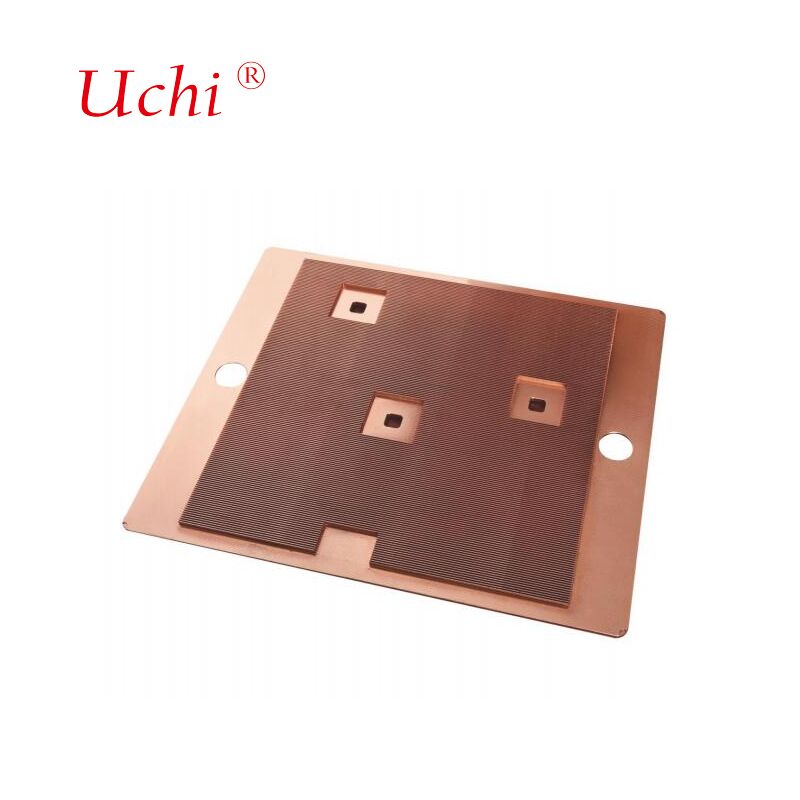

| Resaltar: | Dispensador de calor de tubo de cobre de 600 W,Disipador de calor raspado de la aleta,Disco de refrigeración líquido disipador de calor |

||

Descripción de producto

Sinque térmico de la serie 220 - Sinque térmico de tubos de cobre de 600W

| Tipo de artículo | Dispositivo de calefacción a medida |

|---|---|

| El material | Aluminio, cobre |

| Tamaño | Tamaño estándar o personalizado |

| Colorido | Plata, negro, azul, color de madera, color de revestimiento en polvo RAL, y más |

| Forma de las piezas | Redondo, cuadrado, plano o personalizado |

| El grosor | 0.4mm-20mm o personalizado |

| Aplicación | Iluminación LED, inversor, máquina de soldadura, dispositivo de comunicación, equipo de suministro de energía, industria electrónica, enfriadores/generadores termoeléctricos, sistemas de refrigeración IGBT/UPS, etc. |

| Proceso de producción | Profiles Extrusión → Cortado → Mecanizado CNC (Fresado, Perforación, Tapado) → Desborrado → Limpieza → Inspección → Envasado |

| Acaba. | Anodizado, acabado de molino, electroplataje, pulido, chorro de arena, recubrimiento en polvo, plateado, cepillado, pintado, PVDF, etc. |

| Proceso profundo | Fabricación de aluminio y aluminio sintético |

| Las normas de seguridad | ± 0,01 mm |

| Duración | Duración personalizada |

| Cuota de producción | Bajo MOQ |

| Embalaje | Embalaje estándar para exportación o según se haya discutido |

| OEM y ODM | Nuestros ingenieros pueden revisar y discutir su diseño para soluciones óptimas. |

| Tiempo de entrega | 15-20 días después de la confirmación de la muestra y el pago inicial, o negociado |

Soluciones térmicas avanzadas para tecnología de próxima generación

Con el aumento de la IA y HPC que requieren un procesamiento masivo de datos, los procesadores de próxima generación generarán mucho más calor que los procesadores actuales de gama alta.A medida que la CPU y la GPU TDP (potencia térmica de diseño) continúa aumentandoLas soluciones de refrigeración líquida de BY Thermal maximizan la eficiencia de disipación de calor, mejoran los valores de PUE y aumentan la densidad de computación por rack.La refrigeración líquida está posicionada para desempeñar un papel crucial en la configuración del futuro de los centros de datos.

Aplicaciones en la fabricación de alta gama

Fabricación de semiconductores y chips

Las tecnologías de embalaje avanzadas como el apilamiento 3D conducen a la acumulación de calor dentro de los chips, donde la conductividad térmica del material tradicional se ha convertido en un factor limitante.

Centros de computación/datos de inteligencia artificial

Con la creciente densidad del flujo térmico del chip, los métodos de enfriamiento tradicionales luchan por satisfacer la demanda, haciendo que la gestión térmica sea un factor crítico en la mejora de la potencia informática.

Aeronautica y aeroespacial

El entorno espacial presenta temperaturas extremas y altas condiciones de vacío donde la disipación de calor por convección no es factible, lo que expone el equipo aeroespacial a duras fluctuaciones de temperatura.

Aplicaciones en la vida diaria

- Dispositivos digitalesLos módulos internos de disipación de calor con aletas de refrigeración metálicas en ordenadores, teléfonos móviles y consolas de juegos aseguran un rendimiento sostenido

- Dispositivos de comunicación:Los grandes disipadores de calor garantizan la estabilidad para la transmisión y el procesamiento de datos de alta velocidad

- Aplicaciones para el hogar:Los compresores y los condensadores de unidades externas requieren una disipación de calor eficiente para transferir el calor de los espacios interiores al exterior

- Dispositivos de iluminación:El diseño eficiente de disipación de calor garantiza la eficacia luminosa de la lámpara LED y una larga vida útil

- Vehículos de nueva energía:Los sofisticados sistemas de enfriamiento por líquido mantienen las temperaturas de funcionamiento óptimas

Ventajas de la fabricación de la empresa

Capacidades avanzadas del equipo

Nuestro taller de moldes cuenta con 22 juegos de máquinas de descarga eléctrica (EDM) incluyendo 2 máquinas de EDM espejo MAKINO, 9 máquinas de EDM de corte de alambre (3 Seibu y 1 Sodick importados de Japón),7 máquinas de erosión por chispas, 10 máquinas de rectificación, 2 fresadoras y 1 torno.

Especificaciones de hardware de gran alcance

- Tamaño de la mesa: 500 × 350 mm

- Velocidad de travesía rápida: 5000 mm/min.

- Peso máximo de la pieza: 500 kg

- Peso máximo del electrodo: 50 kg

Alta precisión de mecanizado

Utilizando las tecnologías SuperSpark4 e IES (Sistema Experto Inteligente), proporcionamos una fuente de alimentación adaptativa avanzada y un control de salto para estabilizar el proceso EDM y mejorar la precisión del mecanizado.Nuestras avanzadas tecnologías de generación de ultra-superficie y ultra-borda ofrecen un excelente acabado superficial y calidad metalúrgica.

Aplicaciones del producto

Garantizar la calidad

Mantenemos estrictos estándares de calidad con un equipo de pruebas completo que incluye:

- 1 Máquina de medición de coordenadas

- 1 instrumento de proyección

- 2 máquinas de ensayo de alta presión de agua

- 4 máquinas de ensayo de resistencia térmica

- 2 máquinas de ensayo de fugas de líquido

Compromiso con el servicio al cliente

- Respuesta rápida a todas las consultas

- Precios competitivos con calidad garantizada

- Programación eficiente de la producción

- Soluciones óptimas para el transporte

- Apoyo técnico completo

Preguntas frecuentes

¿Es usted una empresa comercial o un fabricante?

Somos un fabricante profesional de disipadores de calor y placas de enfriamiento de agua con una amplia experiencia y un fuerte equipo técnico, con producción automatizada y mecanizada.

¿Ha exportado bienes antes y a qué regiones?

El 60% de nuestra producción total se exporta a Japón, India, Reino Unido, Canadá, Estados Unidos y Brasil.

¿Cuántos empleados tiene?

Aproximadamente 100 empleados en los departamentos de ventas, compras, ingeniería, control de calidad, almacén y producción.

¿Puede proporcionar muestras si estamos de acuerdo con el diseño?

Sí, proporcionamos muestras para confirmación antes de la producción en masa, junto con dibujos técnicos si es necesario.

¿Qué métodos de embalaje utilizan?

Embalaje personalizado con cajas de cartón normales y tejido o cajas de madera resistentes para una protección óptima durante el transporte.

¿Provee soporte técnico para problemas de producto?

Todos los productos son inspeccionados antes del envío. Para cualquier problema, proporcionamos soluciones técnicas inmediatas.

Quiere saber más detalles sobre este producto